Login

Equipment

Name:

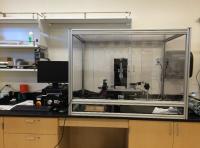

CNC micro milling machine

Equipment Type:

Description:

The Minitech 4 axis CNC micro milling machine can be used for fast prototyping of molds, devices or sample holders. It can be used with polymers or soft metals, to micro-machine complex shapes or precisely drill holes with micro bits. Designs can be implemented using Solidworks and Mastercam software. The stepper motors controlling the stage employ micro-stepping, and a XYZ resolution of 1 μm is achieved. The repeatability of the system, including the spindle run-out, has been experimentally found to be less than 5 μm when working on areas a few centimeters across, which is the dimension typically used for microfluidic systems. X, Y, Z Axis Travel 12.0" x 9.0" x 9.0" (300 x 200 x 200mm) Feed Rates .1 to 150 ipm linear .1 to 50 ipm 3-axis simultaneous Stepper Motors 200 steps per revolution in full step mode, rated at 250 oz. in. Drivers Standard Step Modes: Micro stepping modes up to 12,800 steps per revolution (1 step, 1/2 step, 1/4 step, 1/8 step, and 1/64 stepping modes) Resolution Modes • Standard .0005" full step, .00025 half step • Micro Stepping Modes: .000125" 1/4 step, .0000625" 1/8 step, .0000078125" in 1/64 step Spindle Speeds 1000 RPM to 60,000 RPM Tool Chuck: vacuum chuck

PLEASE USE FOM FOR EQUIPMENT RESERVATIONS